FAQS

RESP-FIT is a national respiratory protective equipment (RPE) fit testing training and accreditation program developed to improve the competency of fit testers against both the Australian and international ISO respirator standards for fit testing. RESP-FIT was developed by the Australian Institute of Occupational Hygienists (AIOH) through close collaboration with many industry stakeholders such as:

→ Current RPE fit testers.

→ State & Territory Regulators.

→ RPE Manufacturers and Distributors.

→ Industry, workers and members of the AIOH.

Our goal is to protect worker’s health by ensuring the respirator, the last line of defense against dust, chemicals or pathogens, can fit properly and prevent leakages causing exposures to the contaminated air.

RESP-FIT provided a program overview during a AIOH Virtual Chapter Meeting on the 8th December. A recording of this video can be viewed here on YouTube or on our news page.

There is clear evidence that real world respiratory protective equipment (RPE) protection factors are improved when there is an RPE fit testing as part of a respiratory protection program (RPP). The specifics of RPE fit testing are coming under increasing scrutiny with such high reliance in many workplaces on RPE as a control. There has been no clear guidance in Australia on what defines a “good” RPE fit test and unfortunately, there are plenty of examples of poor fit testing practice and mis-information in many industries. The implementation of an respirator fit testing training and accreditation program aims to fill this gap in guidance to provide the means for improving the quality of respirator fit testing in Australian workplaces.

No matter the tight fitting respirator brand, the correct protocol and steps must be taken to ensure a reliable fit test and that there is confidence that a true indication of fit (or lack of fit) has been achieved through a validated methodology and by a competent person whether they choose to do it inhouse or engage a service provider.

Yes, there are similar programs like RESP-FIT internationally as below

- FIT2FIT scheme developed and managed by the British Safety Industry Federation (BSIF)

- COMMIT2FIT scheme developed and managed by the New Zealand Occupational Hygiene Society (NZOHS)

The objective of RESP-FIT is to improve worker health protection of those wearing tight fitting respiratory protective equipment, through reliable respirator fit testing by competent fit testers in Australia by

- A standardised training syllabus to improve respirator fit tester knowledge and skills;

- Demonstration of competence through an accreditation process to AS/NZS ISO 16975.3:2023 Section 5.

It provides information and tools for workplaces to make an informed decision on RPE fit testing that is appropriate and suitable for their working environment and controls.

A respirator fit test is a method for checking that a tight fitting facepiece matches the persons facial features and seals adequately. It will also help to identify unsuitable facepieces which should not be used.

There are a number of different internationally recognised fit testing methods being either qualitative (QLFT) or Quantitative (QNFT) which are practiced in Australia. These different methods have pros and cons and may only be suitable for certain types of respirators.

The performance of tight-fitting facepieces depends on achieving an adequate seal between the wearer’s skin and the face seal of the facepiece. We live and work in a diverse world and peoples’ faces vary significantly in shape and size so it is unlikely that one particular type, or size of RPE facepiece, will fit everyone. With many different face shapes, many different mask types and sizes are required. The aim is to select a respirator fits the individual and their facial characteristics. The expected and required respirator assigned protection factor is unlikely to be achieved if the respirator does not fit or isn’t fitted correctly each and every time.

A person conducting a business or undertaking (PCBU)/employer, is required under WHS/OHS law to provide a working environment that is safe and free of risk to health, so far as is reasonably practicable. Decisions on controlling exposure to a hazard should be based on considerations including the likelihood of the hazard or risk occurring, the harm that would result, the availability and suitability of ways to eliminate or reduce the hazard or risk, and the cost of eliminating or reducing the hazard or risk.

PPE is the lowest order on the hierarchy of control and if used/required, must be supplied together with adequate information, training and instruction on the:

- Proper use and wearing of the PPE

- Storage and maintenance of the PPE

- Responsibilities of the workers

There are specific legal duties that must be met when providing PPE (such as tight fitting respirators) which includes ensuring that it is a suitable size, fit and reasonably comfortable. Guidance on this is provided in AS/NZS 1715 which discusses respirator fit testing (for tight fitting respirators) as part of a complete respiratory protective program (RPP) and is an accepted way to meet the legal obligations with regard to supply of suitable and properly fitted respiratory protective equipment (RPE).

State and Territory WHS/OHS regulators may issue notices and fines where the duty holder under the WHS/OHS legislation cannot demonstrate where a respiratory protection program in accordance with the Australian Standard AS/NZS 1715 (which includes respirator fit testing for tight fitting respirators) is implemented.

AS/NZS 1715 does not detail the knowledge/competencies a RPE fit tester should have. Most industries/companies currently use their own definition/level of a “competent person” but what is considered a “competent person” varies significantly. Other international fit testing standards/guidance documents detail minimum knowledge and skills a RPE fit tester should have.

No matter the tight fitting respirator brand there must be confidence that a true indication of fit (or lack of fit) has been achieved through a validated methodology and protocol by a competent person. This competent person may be a occupational hygienist, safety professional, internal who has undertaken appropriate training or a external fit test service provider. Whoever it is, they need to be competent.

RESP-FIT is using AS/NZS 1715 and AS/NZS ISO 16975.3:2023 as the basis for its training and accreditation program. AS/NZS ISO 16975.3:2023 provides detailed guidance to the knowledge and practical skills that fit test operators should have. Below is a excerpt from AS/NZS ISO 16975.3:2023 Section 5 detailing this information as guidance. The RESP-FIT Accreditation assessment is based on these competent person requirements.

5 Competent fit-test operator

5.1 General

Fit-test operators shall be properly trained and demonstrate a proficiency in the fit-test method(s) being used. The RPD programme administrator is responsible for evaluating and verifying the training and qualification of operators. An example of an evaluation form to assess the competency of fit-test operators is given in Annex A.

NOTE Programme administrators can consider the benefits of formal training programmes from outside providers for competent fit-test operators.

5.2 Qualifications

5.2.1 General

Fit-test operators should have adequate knowledge, understanding and practical skills required to conduct a fit test. Fit-test operators shall be familiar with this document along with the appropriate sections of the RPD programme concerning RPD fit testing, purpose and applicability, specific roles and responsibilities, interference concerns, inspection, cleaning, maintenance and storage in ISO/TS 16975-1 (now adopted as SA/SNZ ISO TS 16975.1:2023) and ISO/TS 16975-2 (now adopted as SA/SNZ ISO TS 16975.2:2023).

5.2.2 Knowledge of RPD used for the fit test

Fit-test operators shall demonstrate a general knowledge of RPD used by the wearer in the workplace by:

a)a basic understanding of the selection of adequate and suitable RPD;

b)identifying RPD components and their functions;

c)demonstrating RPD inspection, cleaning, and maintenance procedures;

d)identifying different makes, models, styles, and size RPD as alternatives;

e)discussing RPD capabilities and limitations as related to RPD fit testing;

f)demonstrating and evaluating correct donning and doffing procedures including wearer-seal checks.

5.2.3 Knowledge of the fit-test method

Fit-test operators shall demonstrate knowledge and application of the fit-test method(s) being used, by:

a)explaining the purpose of fit testing;

b)explaining fit-testing procedures;

c)explaining the capabilities and limitations of the fit-test method;

d)identifying indications of erroneous fit-test results (e.g. quantitative fit factors that are unusuallylow or high);

e)demonstrating knowledge of the health and safety hazards associated with the chemicals and/or equipment used in the fit test.

5.2.4 Ability to set up and monitor the function of fit-test equipment

Fit-test operators shall demonstrate the ability to set up all applicable equipment and monitor its function for the fit-test method(s) being used, by:

a)selecting the proper RPD filters for the fit-test method;

b)preparing, inspecting and performing operational checks of fit-testing equipment and materials;

c)proper assembly and use and positioning of probes and adapters for quantitative fit-test methods;

d)identifying possible issues with the fit-test equipment.

5.2.5 Ability to conduct the fit test

Fit-test operators shall demonstrate the ability to conduct the fit test(s) being used, by:

a)properly evaluating persons being fit tested and understanding when to refuse to conduct a fit test by recognizing interference concerns (such as/ due to) facial characteristics, facial hair or other problems that may interfere with RPD fit or the fit test;

b)explaining the fit-test purpose and procedures to persons being fit tested;

c)observing that the correct donning procedure is used without assisting the person being fit tested;

d)observing that wearer-seal checks are performed according to the procedures recommended bythe RPD manufacturer;

e)observing the person being fit tested throughout the entire fit-test procedure to ensure it is performed correctly;

f)conducting the chosen fit-test method according to the procedures specified in 8.5 and 8.6;

g)evaluating and recording the results of the fit test;

h)explaining the result of the fit test and the meaning of the result to the wearer;

i)performing RPD cleaning and disinfection according to the information supplied by the manufacturer;

j)removing the fit-test adapter and reassembling valves, etc., if applicable prior to use in the workplace.

5.2.6 Ability to identify likely causes of fit-test failure

Fit-test operators shall demonstrate the ability to identify causes of fit-test failure such as:

a)improperly donned or adjusted RPD;

b)incorrectly assembled or damaged RPD;

c)incorrect size, shape or style RPD.

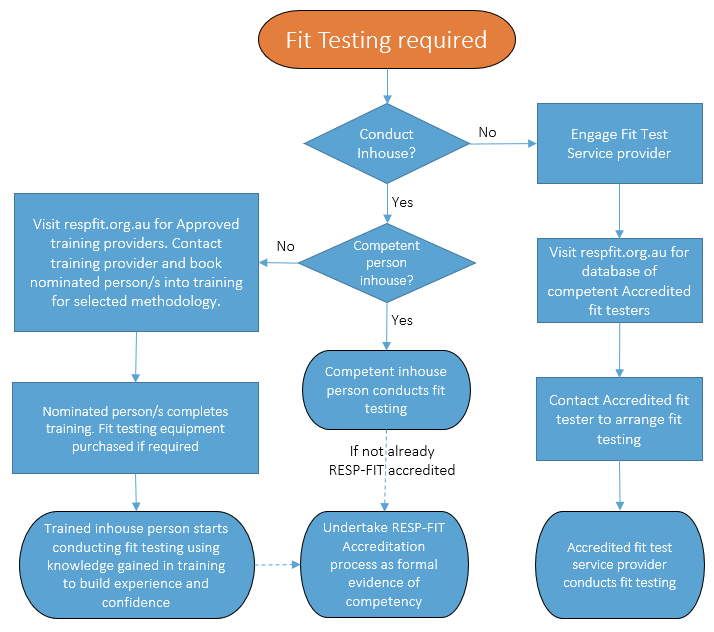

A fit tester could be an inhouse person or be an external fit test service provider, but whoever it is they must be competent in performing fit testing to ensure a reliable fit test result. Each organisation or individual need to determine what is appropriate for their specific circumstance. Do you have the resources or ability to purchase fit testing equipment e.g.? Do you have suitable people that are competent or that can be trained to build experience over time? How many people require fit testing? What methodology will be selected? There are many factors that need to be evaluated to whether a inhouse person or external fit test service provider would be most appropriate.

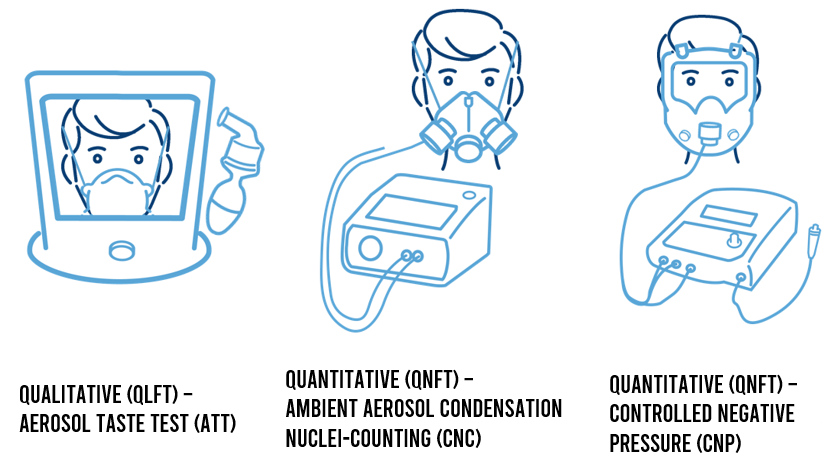

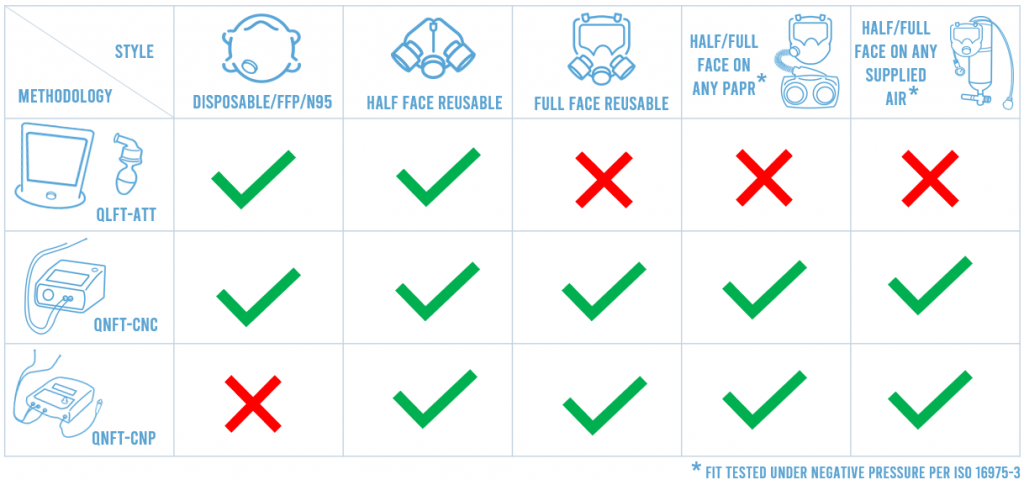

Internationally there are a number of accepted and validated fit test methodologies. The three most common methodologies, and the ones covered under the RESP-FIT program are

- Qualitative (QLFT) – Aerosol Taste Test (ATT)

- Quantitative (QNFT) – Ambient aerosol condensation nuclei-counting (CNC)

- Quantitative (QNFT) – Controlled Negative Pressure (CNP)

RESP-FIT is not covering practical training or assessing competence for other fit test methodologies, such as Vapour qualitative fit test with isoamyl acetate(IAA)/banana oil or irritant smoke.

Qualitative (QLFT) – Aerosol Taste Test (ATT) most commonly uses saccharin or Bitrex as the challenge aerosol agent. Providing the person can taste the selected challenge agent, if they can’t taste the aerosol wearing the disposable/ filtering facepiece or a half face reusable respirator fitted with a particulate filter while undertaking the set movement activities then an acceptable fit has been achieved. The methodology is only suitable for disposable/filtering facepieces and half face reusable respirators as it is determined to have an equivalent fit factor of 100. Full faces respirators require a QNFT method which can accurately determine a higher fit factor.

Quantitative (QNFT) – Ambient aerosol condensation nuclei-counting (CNC) uses the ambient aerosols in the immediate fit testing environment to measure the amount of aerosol inward leakage getting inside the respirator compared to the amount outside the respirator. This ratio of reduction indicates the fit factor being achieved during the fit test. Different respirators types have different recommended minimum fit factors to be achieved to be deemed an adequate fit. This method can fit test all styles of tight-fitting respirators such as disposable/filtering facepieces, reusable half face and reusable full face.

Quantitative (QNFT) – Controlled Negative Pressure (CNP) method uses the principle of ‘controlled negative pressure’ – it creates a slight negative pressure inside of the respirator being tested (while the wearer holds their breath and remains still) and monitors the pressure in order to measure any face seal leakage. This method can fit test reusable half face and reusable full-face respirator, but it is NOT suitable for disposable/filtering facepieces (FFP).

Each method has its pros, cons and limitations which workplaces should be aware when selecting a suitable methodology. Whatever methodology is selected it must be undertaken by a competent person to have confidence that a accurate indication of fit (or lack of fit) has been achieved.

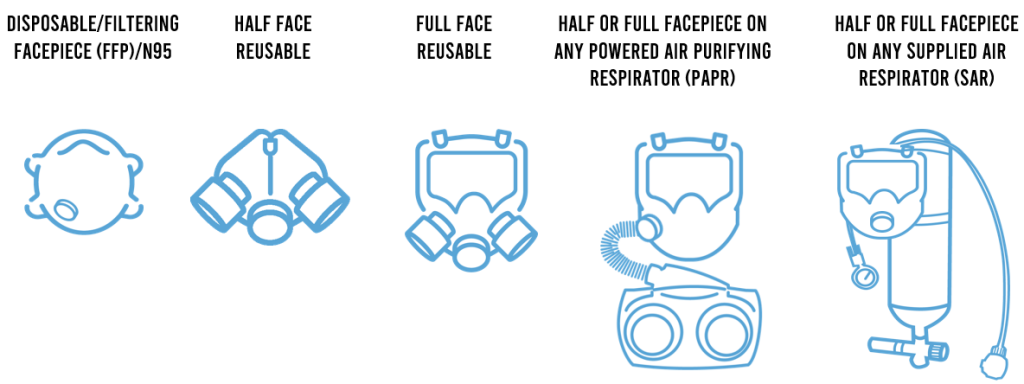

All types of tight-fitting respirators (negative and positive pressure) must be fit tested as required by AS/NZS 1715, AS/NZS ISO 16975.3:2023 and all other international RPE guidance.

This includes all disposable/filtering facepieces (FFP), reusable half face, reusable full face including those attached to a powered air purifying respirator (PAPR) or supplied air source such as SCBA cylinder and compressed airline hose.

It is commonly asked why do positive pressure tight-fitting respirators require fit testing? Generally, the assigned protection factor for these positive pressure combinations is higher than a negative pressure equivalent style facepiece. This higher assigned protection factor is based on the wearer achieving an adequate seal in addition to the positive pressure. A positive pressure respirator would be temporarily converted to be negative pressure or use a negative pressure respirator with an equivalent sealing surface to conduct the fit test.

Positive pressure loose fitting headtops or hoods connected to a powered air purifying respirator (PAPR) or a compressed airline hose. The amount of positive pressure inside the headtop or hood pushes out the close seal preventing contaminants to enter into the respirator. Generally these combinations have a lower assigned protection than a positive pressure tight fitting combination.

RESP-FIT is not recommending any specific Australian or international protocol over another. In addiotion to AS/NZS ISO 1675.3:2023, there are a number of international protocols such as ISO 16975-3:2017, INDG-479 (UK), ANSI Z.88.10 (US) and OSHA 1910.134 Appendix A (US). The most commonly used protocol in Australia would be the OSHA 1910.134 Appendix A (US). Whatever protocol is selected, the specific requirements of that protocol must be followed which is the responsibility of the competent fit tester to achieve a reliable outcome.

The time to complete a fit test varies depending on a few different factors. Different methodologies and protocols have different requirements which vary the time required to complete the test. The is the time to perform the test but additional time require before the test and after the test. This may include (depending on the methodology)

- Sensitivity test (if applicable)

- Preparation of facepiece for the test

- Instruction of the wearer in the fit test exercises

- Donning and performing the wearer User seal check of the facepiece fit

- 5 minute Comfort assessment period

- The actual fit test

- Removal of facepiece

- Explanation of the results of the fit test

- Training on selection, use, donning, maintenance of the respirator or any other questions from the subject.

Additional fit tests – repeats due to initial failure or for more than one respirator – will need to be accommodated or rescheduled. Fit testing takes time!

Respirator fit testing is required prior to the initial use of a tight fitting respirator and/or when a different size, style, model or make is used. A fit test should be repeated when a person has a significant change in body weight, a change to the face in the sealing area (e.g. scarring facial surgery), dental changes and/or wearer discomfort.

AS/NZS IOS 16975.3:2023, AS/NZS 1715, ISO 16975-3:2017 and OSHA 1910.134 all recommend periodic fit testing be conducted annually to confirm ongoing fit over time.

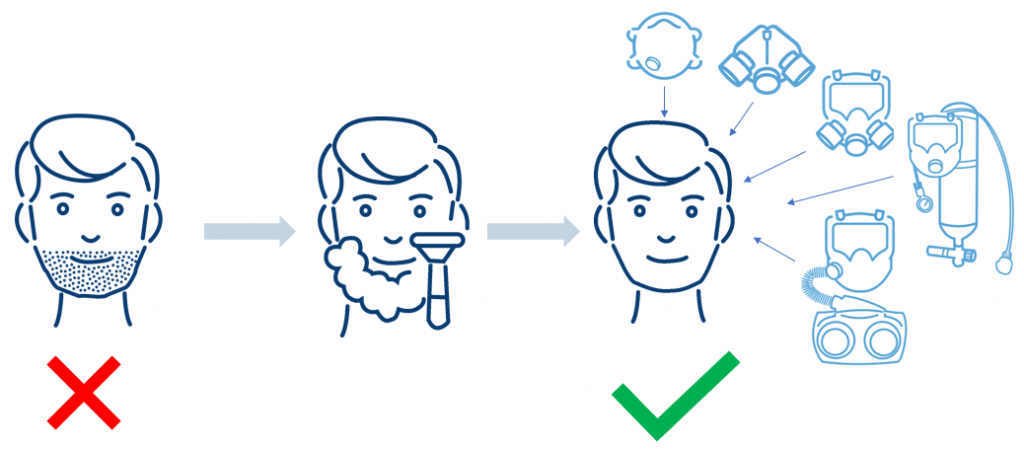

Many studies show that the presence of facial hair between the sealing surface area and the skin can significantly reduce the expected level of protection. Many hazards of concern e.g. asbestos, silica, DPM, mould, bioaerosols are many times smaller than a single facial hair and can bypass between them. Gases and vapours can bypass between facial hair as well. A tight-fitting respirator has been selected as part of a control strategy to provide an expected level of protection. With facial hair the expected protection is not predictable or reliable.

A fit test confirms a fit between a wearer and a particulate style, brand or size can be achieved. A user seal check (fit check) is performed each time the respirator is donned to confirm a fit in conjunction with the previously conducted fit test.

Wearers of a tight fitting respirator can either perform a positive-pressure or negative-pressure seal check:

- A positive-pressure check means blocking the exhalation valve on a half or full facepiece respirator or covering the respirator surface on a filtering facepiece, usually by using your hands, and trying to breathe out. If slight pressure builds up, that means air isn’t leaking around the edges of the respirator.

- A negative-pressure check involves blocking the intake valves on a half or full facepiece respirator or covering the respirator surface on a filtering facepiece, typically using your hands and trying to breathe in. If no air enters, the seal is tight.

A simple analogy is a fit test is like sizing up a shoe, however the shoe needs to be correctly laced up each time it is worn. Both are required to have confidence that a fit can be achieved and then in turn is being achieved on the job.

In some industries, a fit test and user seal check (fit check) are viewed as being equivalent which is not the case. Many studies have shown that a fit test and user seal check (fit check) are not equivalent.

If a person is unable to achieve an adequate fit on a particular style, brand, size or model, this is not a reflection on the person themselves or necessarily the respirator itself. A different style, brand, size or model should be selected to be fit tested until an adequate fit can be demonstrated. This may be the next style, brand, size or model selected or it may take a few times.

Generally a style, brand, size or model should only be attempted to be fit tested twice, before selected another style, brand, size or model. We want the wearer to be easily able to achieve that adequate seal than trying many many times and pulling the straps as tight as possible to get a seal. Most workers are not going to attempt to fit a respirator multiple times on the job, so we want them to get seal on that first attempt.

Respiratory Protective Equipment (RPE) can have some impacts on the physiological and psychological aspects of performing a task. RPE can increase the work of breathing, impair vision and speech, and can make workers more vulnerable to heat stress and feelings of claustrophobia. Given this knowledge, RPE selection needs to consider the psychological and physical suitability of wearers. It is important to know that some pre-existing health conditions (such as breathing disorders, skin allergies or even heart conditions) may worsen by wearing any RPE, or certain types of RPE.

An effective respiratory protective program (RPP) program should cover the physiological suitability to wear respirators. Workers who are required to do tasks that require RPE must be physically able to perform the work while using the respirator. The PCBU/employer is responsible to ensure that workers are fit to wear the selected and required RPE for their job tasks. If unsure, employers should arrange for appropriate health assessment. It is recommended this is considered before any employee is fit-tested.

Refer AS/NZS 1715 Section 6 Medical and Physical Considerations for further guidance. Additional resources and references are provided in the RESP-FIT FAQs.

Contact Australia and New Zealand Society of Occupational Medicine ANZSOM (website) to find a Occupational Physician

All these terms are based around the ‘Protection Factor’ concept which is the reduction of exposure level from outside the respirator compared to inside the respirator.

A Fit Factor (FF) is the numerical result that is produced by the quantitative RPE fit test to confirm if an adequate fit can be achieved. For a QNFT-CNC fit test, it is calculated as the ratio of the two aerosol concentrations measurements outside of the respirator divided by the concentration inside of the respirator. A QNFT-CNP fit factor is the ratio of inspiratory flow rate to the measured leakage flow rate. A passed QLFT-ATT fit test is deemed to be equivalent to a fit factor of 100. A fit factor number cannot be compared directly to what workplace protection factor will be achieved on the job by a wearer.

An Assigned protection factor (APF) is the level of protection that can be expected by 95% of all clean shaven, fit tested and trained wearers on the job. AS/NZS 1715 specifies the different assigned protection factors for various combination of respiratory products. This is the number that is used when selecting a respirator on the job as part of the Respiratory Protection Program (RPP).

A Workplace Protection Factor (WPF) is the level of protection actually experienced by the wearer.

Different countries and standards specify different fit factor pass levels for different respirator types. Refer to the specific protocol being used for the minimum fit factor required. If unsure, a general rule of thumb is to use a fit factor at least 10x the assigned protection factor as specified in AS/NZS 1715.

As an example a P2 disposable/filtering facepiece (FFP) respirator or reusable half face respirator has an assigned protection factor (APF) of 10. Therefore the minimum fit factor pass required would be 100.

If a full face respirator with a P3 filter is being fit tested, it has a APF of 100. Therefore the minimum fit factor pass required would be 1000 following the 10x the assigned protection factor rule of thumb which RESP-FIT reccomends.

NOTE: Different protocols do specify the minimum fit factor pass level, so be sure to be aware of these.

QNFT-CNC

- OSHA 1910.134 – Pass level of at least 100 for half face respirators (filtering facepeice/disposable respirators & reusable half face). Pass level of at least 500 for full face reusable respirators.

- INDG479 – Pass level of at least 100 for half face respirators (filtering facepeice/disposable respirators & reusable half face). Pass level of at least 2000 for full face reusable respirators.

QNFT-CNP

- OSHA 1910.134 – Pass level of at least 100 for half face respirators (reusable half face). Pass level of at least 500 for full face reusable respirators.

- INDG479 – Pass level of at least 100 for half face respirators (reusable half face). Pass level of at least 2000 for full face reusable respirators.

The different protocols specify whether a fit test subject is required to be sitting, standing, or performing a specific exercise during a fit test. Generally these protocols require the fit test subject to be standing while performing the exercises/movements. In addition to standing INDG479 requires the fit test subject for QNFT-CNC (except bending exercise) to be cycling on an exercise bike, walking on a treadmill or carrying out a stepping exercise.

Refer to the selected protocol for specific guidance around standing, sitting, exercises, movement for the selected methodology.

For fit test subjects who are permanently unable to stand i.e. in a wheelchair, it would be a reasonable adjustment to conduct the fit test for them sitting down or the position/posture they would be in on the job.

For fit test subjects who are unable to stand for a temporary period i.e. injury, it would also be a reasonable adjustment to fit test them sitting down or the position/posture they would be in on the job. However, when they are able to stand or back to normal condition, they must be fit tested again in the standing position per the protocol requirements.

The 5 minute comfort assessment period is required as part of the overall fit test. Its objective is to allow the respirator to settle on the fit test subject to assess it is comfortable for the wearer before starting the fit test. If a respirator is not comfortable (even if a adequate fit can be achieved), the wearer is likely to adjust or remove the respirator on the job and protection will reduced or not achieved at all. Hence this is a critical in evaluating a tight fitting respirators suitability to the wearer.

Each of the protocols specific this 5 minute comfort assessment period to be conducted as part of the fit testing process

- AS/NZS ISO 16975.3:2023 Section 6.6.2

- ISO 16975-3 Section 6.6.2

- OSHA 1910.134 Appendix A Part I.A.5

- ANSI Z88.10-2010 Section 6.6.2

Respirators are often worn with other head mounted PPE such as safety eyewear, earmuffs, hard hats in the workplace. This other PPE will often impact how and where a respirator may be worn affecting the fit. The objective of a fit test is to replicate how a respirator will be worn on the job. If a fit a test is conducted without any other PPE and other PPE is required on the job, then this is not truly representative of the real factors impacting the fit. Someone may pass a fit test without any other PPE, but when worn on the job with PPE a adequate fit may not be able to be achieved. Therefore it is critical that other PPE be worn during a fit test to provide a accurate indication of fit.

These products are designed to fit loosely on the wearers face to prevent the spread of aerosols and droplets into the immediate environment as a source control. They are not considered PPE or as respiratory protection products and do not provide any rated level of wearer respiratory protection. Therefore they are NOT classified as a tight fitting respirator and fit testing is not applicable.

It depends on what methodology and protocol is being used for the fit test.

In a QLFT-ATT fit test, if the fit test subject can taste the aerosol in any exercise the test is stopped. The subject would then need to remove the hood, and remove the respirator after allowing for the fit test operator to examine the fit, to wipe their lips/face down and or wash their mouth to confidently remove any aerosol residue. The taste threshold screening test is then conducted again before beginning a new test with a adjusted respirator or a new style/size alternative. So a fail in one exercise is a failed test.

In a QNFT-CNC fit test it depends on the selected protocol.

- Under the OSHA and ISO protocols they state it is the overall quantitative fit factor (QNFF) that must be equal or greater than the required fit factor (RFF). Under these protocols an individual fit test exercise may fail, but provided the overall QNFF above the RFF is acceptable a fit test may be deemed a pass. In this circumstance, the competent fit test operator should be aware of the failed fit test exercise and the amount it failed by. There potentially could be a situation where the passed fit test exercises are much higher than the RFF and the failed fit test exercise is considerably lower than the RFF, but on average the QNFF is above the RFF. This should be of concern as that specific exercise may be a frequent movement performed in the workplace. To address this concern, RESP-FIT recommends that fit test operators when using the OSHA or ISO protocol to manually stop/fail a fit test whenever a single exercise fails irrespective of the QNFF at that point in time. This will ensure that an adequate pass is achieved on all exercises.

- The INDG479 protocol for QNFT-CNC, requires that all fit test exercises must be passed which addresses the potential situation described above.

NOTE: OSHA and ISO protocols specify minimum requirements like any standard or legislation. The RESP-FIT reccomendation improves worker fit testing outcomes higher than these minimum requirements and is in line with the other main international protocol INDG479.

In a QNFT-CNP fit test, a failed fit test exercise may be reattempted where there is an obvious issue affecting the result. This may be an obvious gap in the seal, hair obstructing the seal, the fit test subject had trouble adequately hold their breath or operating the trigger. Diligence should be paid to addressing these potential factors prior to starting the fit test. If after two (2) attempts a fit is unable to be achieved a new respirator style or size should be selected and a new fit test undertaken.

It is the opinion of RESP-FIT Fit that in order to carry out a competent fit test, the fit test must be carried out on the basis of one (1) fit tester to one (1) respirator wearer.

This is the position for both Qualitative and Quantitative fit test methods.

However, we accept that there are individual fit testers whose skill level in managing the Quantitative fit test method using a CNC method is such that they could competently conduct fit testing for two (2) respirator wearers simultaneously.

However, RESP-FIT is only assessing competence on the basis of one (1) fit tester to one (1) respirator wearer.

No. Completion of an Approved RESP-FIT course does NOT make a successful attendee a RESP-FIT Accredited Fit Tester. Successful attendees receive a certificate of attendance from the approved training provider as evidence of attending this course. Completing an Approved RESP-FIT course is not a designation of competence from RESP-FIT or the AIOH.

To become a RESP-FIT Accredited Fit Tester, a person must complete the Accreditation assessment process which is not the basic assessment part of an Approved RESP-FIT course. Visit the “Join as a Accredited Fit Tester” page or download the “Accreditation Applicant Handbook” from the documents page for further details on the accreditation process.

RESP-FIT is aware of the recent adoption of a beard covering technique being used in fit testing tight fitting respirators, particularly in Healthcare. This technique, known as the Singh Thatta, involves the use of an exercise resistance band wrapped around a wearers chin/beard and tied up on top of the head to create a smoother surface over the beard or facial hair, aiming for a better sealing surface area. Disposable balaclavas have also been used in this way to try and improve the tight fitting seal.

All international standards, including AS/NZS ISO 16975.3:2023, AS/NZS 1715:2009, ISO 16975-3:2017, OSHA 1910.134 and others, clearly state that there should be no facial hair on a wearers’ face underneath a tight-fitting respirator sealing surface area. Facial hair prevents an adequate seal from being achieved, and the level of protection is neither reliable nor predictable.

RESP-FIT does NOT recommend the use of this technique for a number of reasons as outlined in the following position statement.

A CNC instrument grows the microscopic particles then, counts the particles inside a respirator and compares them to the particles counted on the outside of the respirator (Cout/Cin), producing a fit factor. The CNC instrument counts all particles (in the specified size range) and operates on the premise that all particles within the respirator sample have come via the face seal leakage pathway.

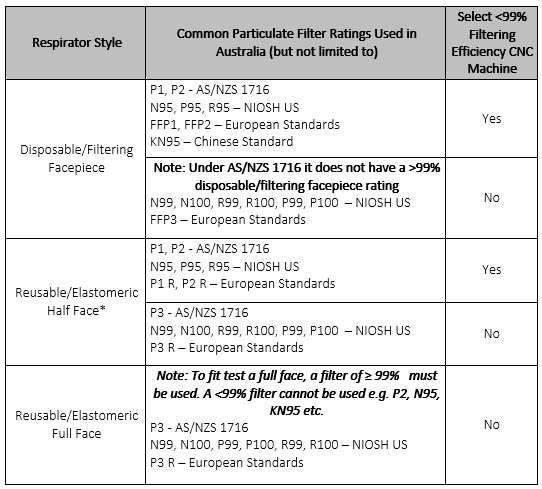

When setting up a respirator in a CNC instrument it is critically important to know when to select the <99% filtering efficiency option or not. Whether it needs to be selected is based upon the filtering efficiency of the particulate filter media used in the fit test. Refer to Appendix A for screenshots of different CNC instrument software and screens.

If the filtering efficiency of the particulate filter media being used in the fit test is ≥ 99% such as P3, N100, P100, R100, FFP3 or P3 R (but not limited to), the <99% filtering efficiency DOES NOT need to be selected.

If the filtering efficiency of the particulate filter being used in the fit test is < 99% such as P1, P2, N95, R95, P95, KN95 FFP1 or FFP2 (but not limited to), the <99% filtering efficiency DOES need to be selected.

These particulate filter standards (AS/NZS, NIOSH, EN etc) ratings allow a certain amount of the standard test aerosol (being the most penetrating particle size) to penetrate the filter and still meet certain ratings. When <99% filtering efficiency is selected the CNC instrument counts a specific size of particles (reduced range) rather than a broader range of sizes (which is why the particle count goes down when this is selected). When the <99% filtering efficiency button is selected, a reduced range of particles is counted by the CNC instrument, eliminating the most penetrating particle sizes (MPPS). The particle sizes that are counted are known to be captured at >99% for these rated particulate filter levels. As a result, we are truly testing the seal of the respirator as a gap in the seal is the only way these particles could have entered and been counted in the facepiece sample.

If the <99% filtering efficiency is not selected when fit testing using P1, P2, N95, R95, P95, KN95, FFP1 or FFP2 filter during the fit test, the MPPS particles will be penetrating/passing through the filter (which is allowable per the standard rating). This fit test method assumes that all counted particles have gone through the face seal pathway only, not through the filter. This will lead to a false negative result (i.e., potentially failing good fitting respirators and not knowing it).

A gas/vapour cartridge cannot be used for a fit test UNLESS a suitable rated particulate filter has been attached/stacked to it. A fit test that is only conducted using a gas/vapour cartridge, that result should be voided/discarded and another fit test with an appropriate particulate filter conducted.

Do not copy or reproduce information without prior approval from RESP-FIT.