RESP-FIT has been hearing feedback through its approved training providers and observing through the accreditation process a common misunderstanding/confusion around when to select the <99% filtering efficiency for condensation nuclei counter (CNC) instrument during the respirator set-up. RESP-FIT has published a document to help provide clarity on when it is to be selected and why it is important to achieving reliable fit testing outcomes. The information in this document is provided below, in the FAQs, PDF download as well as the RESP-FIT documents page.

A CNC instrument grows the microscopic particles then, counts the particles inside a respirator and compares them to the particles counted on the outside of the respirator (Cout/Cin), producing a fit factor. The CNC instrument counts all particles (in the specified size range) and operates on the premise that all particles within the respirator sample have come via the face seal leakage pathway.

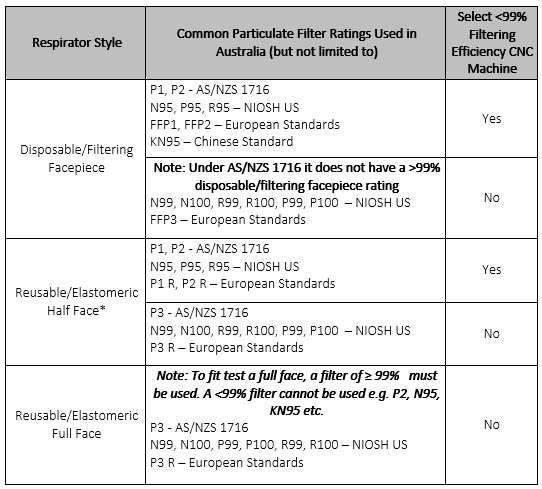

When setting up a respirator in a CNC instrument it is critically important to know when to select the <99% filtering efficiency option or not. Whether it needs to be selected is based upon the filtering efficiency of the particulate filter media used in the fit test. Refer to Appendix A for screenshots of different CNC instrument software and screens.

If the filtering efficiency of the particulate filter media being used in the fit test is ≥ 99% such as P3, N100, P100, R100, FFP3 or P3 R (but not limited to), the <99% filtering efficiency DOES NOT need to be selected.

If the filtering efficiency of the particulate filter being used in the fit test is < 99% such as P1, P2, N95, R95, P95, KN95 FFP1 or FFP2 (but not limited to), the <99% filtering efficiency DOES need to be selected.

These particulate filter standards (AS/NZS, NIOSH, EN etc) ratings allow a certain amount of the standard test aerosol (being the most penetrating particle size) to penetrate the filter and still meet certain ratings. When <99% filtering efficiency is selected the CNC instrument counts a specific size of particles (reduced range) rather than a broader range of sizes (which is why the particle count goes down when this is selected). When the <99% filtering efficiency button is selected, a reduced range of particles is counted by the CNC instrument, eliminating the most penetrating particle sizes (MPPS). The particle sizes that are counted are known to be captured at >99% for these rated particulate filter levels. As a result, we are truly testing the seal of the respirator as a gap in the seal is the only way these particles could have entered and been counted in the facepiece sample.

If the <99% filtering efficiency is not selected when fit testing using P1, P2, N95, R95, P95, KN95, FFP1 or FFP2 filter during the fit test, the MPPS particles will be penetrating/passing through the filter (which is allowable per the standard rating). This fit test method assumes that all counted particles have gone through the face seal pathway only, not through the filter. This will lead to a false negative result (i.e., potentially failing good fitting respirators and not knowing it).

A gas/vapour cartridge cannot be used for a fit test UNLESS a suitable rated particulate filter has been attached/stacked to it. A fit test that is only conducted using a gas/vapour cartridge, that result should be voided/discarded and another fit test with an appropriate particulate filter conducted.

Please refer to the table below to assist in when to select the < 99% filtering efficiency option in your CNC instrument respirator set-up.

*It is common practice that many fit testers will use a ≥99% particulate filter e.g. P3, on Reusable/Elastomeric Half Face respirators as generally, they will also connect to the same brand/connection type reusable/elastomeric full face as part of their fit testing equipment. If fit testing a Reusable/Elastomeric Half Face and changing between <99% and ≥99% particulate filters, be sure to review your respirator set up each time is correct to the filter efficiency being used.

Should you have any questions, please email respfit@aioh.org.au